Engineering

Our company will update industry news and company style in a timely manner. Thank you for your attention!

01.

Equipment Manufacture

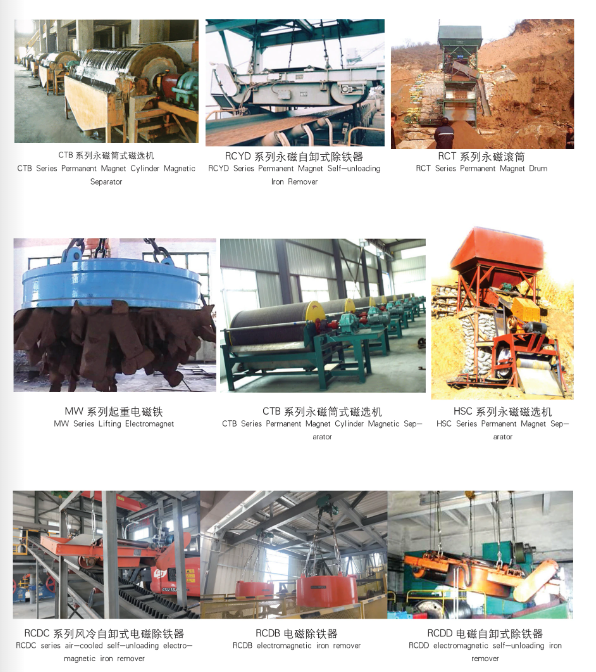

With more than 30 years experience in the R&D of magnetic separation technologies, we specialize in manufacturing superconducting magnetic separators, electromagnetic wet & dry high intensity magnetic separators, permenant wet & dry magnetic separators, overhead magnetic iron separators, eddy current separators, ultra-fine grinding and classifying equipment, mining compete set equipment.

02.

Beneficiation Plant Design

When clients require Engineering & Consulting services, our firm mobilizes experienced technicians to initially analyze the minerals. Subsequently, we offer a concise quotation for the concentrator’s comprehensive construction and an economic benefit analysis tailored to the concentrator’s size, integrating various specialties. Mine consulting can provide more detailed and precise information. The objective is to furnish customers with a comprehensive understanding of their ore processing plant, encompassing the mine’s value, minerals’ beneficial elements, available beneficiation processes, the extent of beneficiation, necessary equipment, and an estimated construction timeline.

03.

Training

The simultaneous training of workers and the installation and commissioning can reduce the construction period costs for customers. Worker training serves two purposes:

1. To enable our customers’ beneficiation plants to commence production as soon as possible, thereby achieving benefits.

2. To train the customers’ technician teams, ensuring the smooth operation of the beneficiation plant.

04.

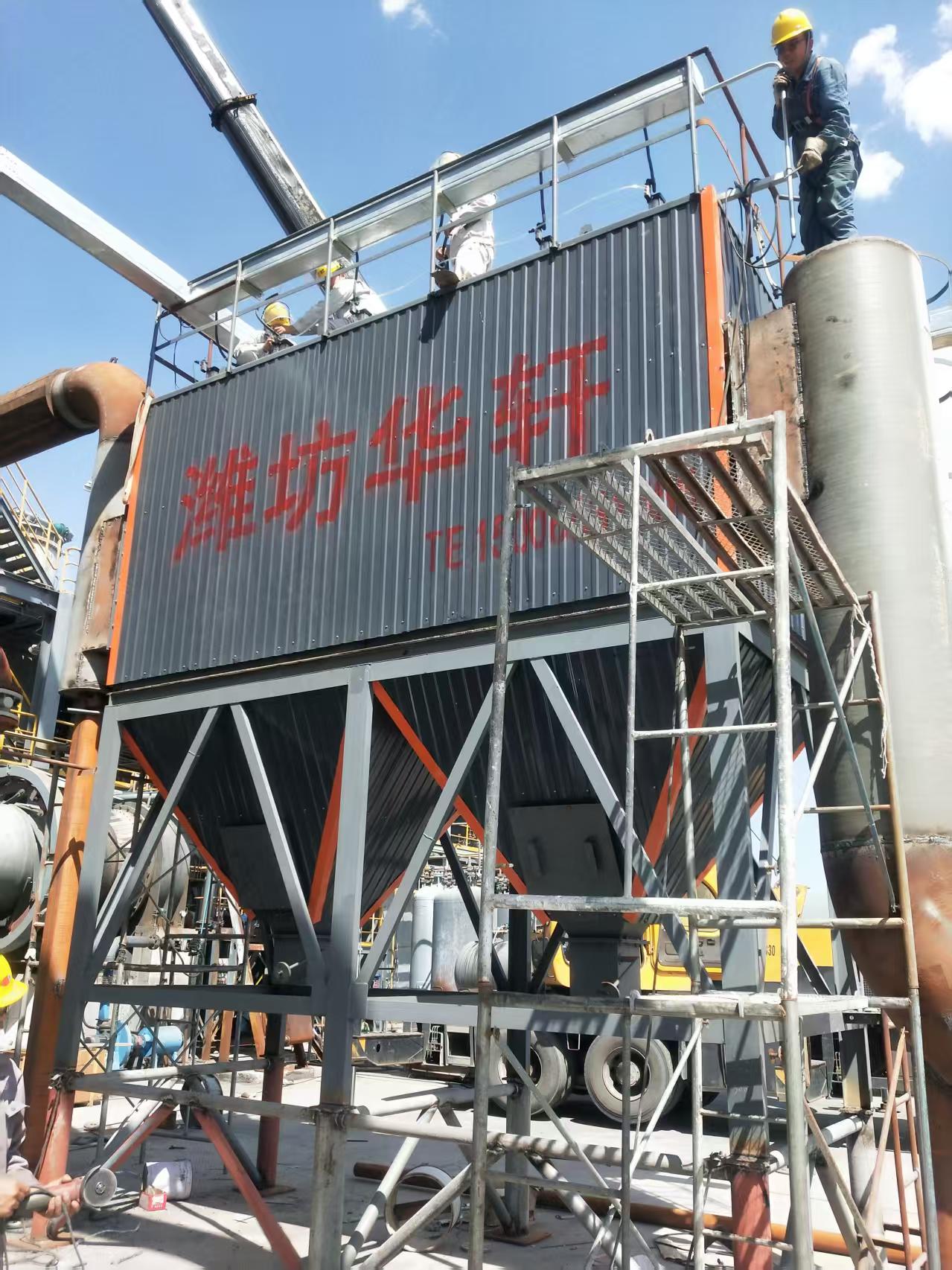

Installation And Commissioning

The installation and commissioning of equipment are meticulous and rigorous tasks with strong practical implications, directly impacting whether a plant can meet production standards. The proper installation of standard equipment directly affects its performance, while the installation and fabrication of non-standard equipment directly influence the stability of the entire system.

Operation

05.

EPC services encompass reaching the production capacity designed for the customer’s beneficiation plant, achieving the expected product granularity, ensuring product quality meets the requirements, meeting the design index of recovery rate, fulfilling all consumption indexes, controlling production costs effectively, and maintaining stable operation of process equipment.

06.

Packing And Shipping

To ensure that equipment arrives at the dressing plant in good condition, HONGLIU MAGNETIC employs seven packaging methods: Nude Packing, Rope Bundle Packing, Wooden Packaging, Snakeskin Bag, Airform Winding Packing, Waterproof Winding Packing, and Wood Pallet Packing. These methods are designed to prevent potential transportation damage, including collisions, abrasion, and corrosion.

Reflecting the demands of international long-distance maritime and post-shore transportation, the chosen packing types include wooden cases, cartons, bags, naked, bundled, and container packing.

To expedite the identification of goods during the installation process and to minimize the workload of on-site lifting and handling, all cargo containers and large unpacked goods are numbered. The mine site is instructed to unload these at specific locations to facilitate handling, lifting, and locating.