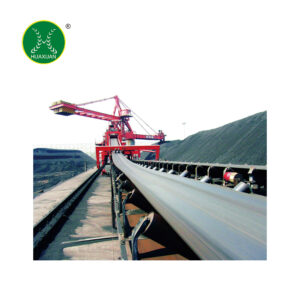

The RCYD suspended self-discharging permanent magnetic iron remover is a specialized device designed for efficient iron impurity removal in material handling lines. Mounted in suspension above conveyor belts or material flow channels, it utilizes high-strength permanent magnets to generate a strong magnetic field, effectively adsorbing ferrous contaminants (such as iron nails, scraps, or blocks) mixed in bulk materials like ores, coal, aggregates, or coke.

Featuring an integrated self-discharging mechanism—typically composed of a drive system, scraper, or rotating structure—it automatically separates the adsorbed iron impurities from the magnetic field and discharges them to a designated collection area, eliminating the need for manual cleaning. This automation ensures continuous operation without interrupting the production line.

Constructed with a robust frame and wear-resistant components, the device is built to withstand harsh industrial environments, including dusty, humid, or high-vibration conditions. Its permanent magnetic system delivers long-lasting magnetic force with minimal energy consumption (only requiring power for the discharge drive, if applicable), ensuring stable performance and low maintenance costs.

Widely applied in mining, coal processing, construction materials, power, and metallurgy industries, the RCYD iron remover protects downstream equipment (such as crushers, grinders, and conveyors) from damage caused by iron impurities, enhances material purity, and guarantees the safety and efficiency of production processes.