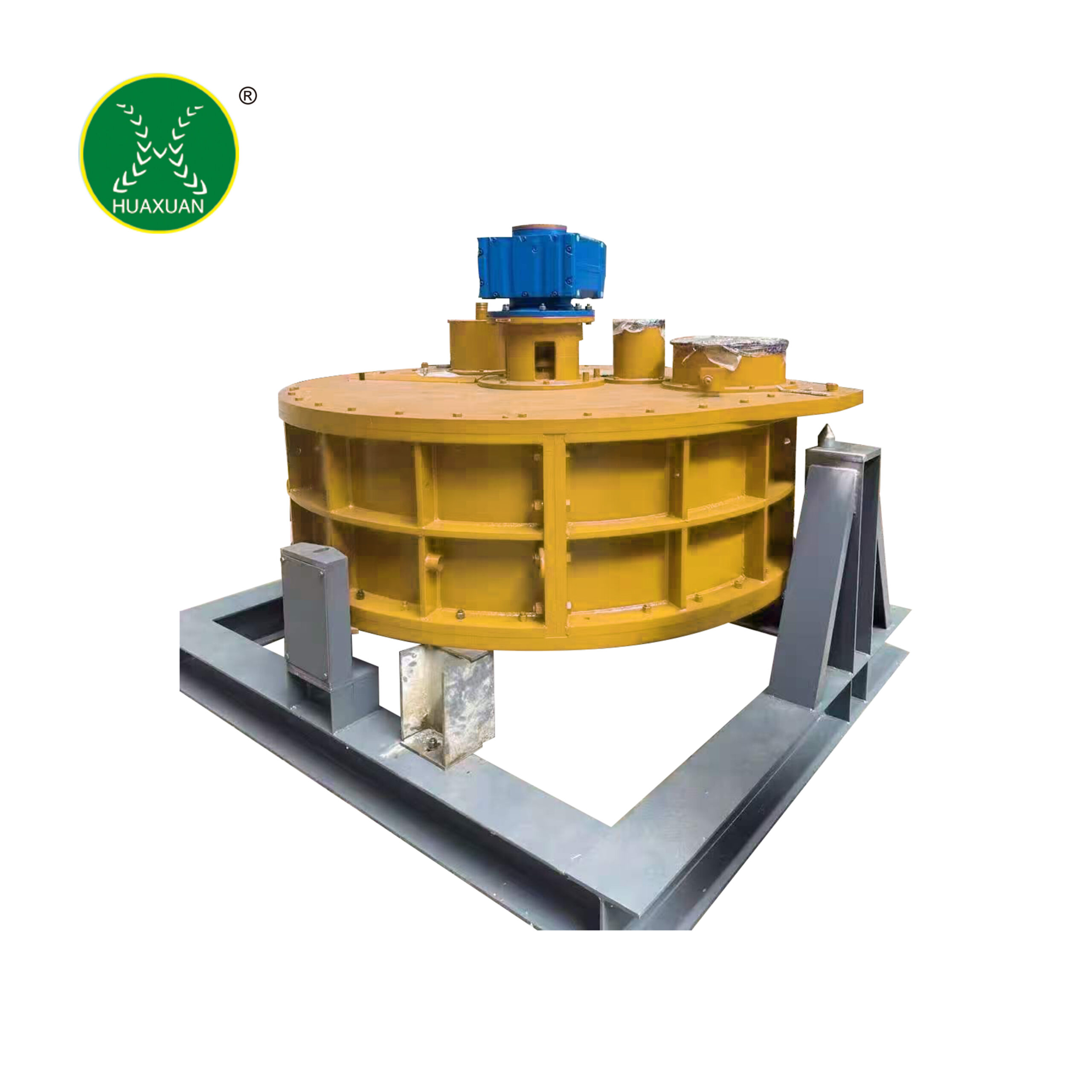

Principle:

the powder rotr scale adopts a balance struclure to weigh materilals, The balance body composed of a motor. impeller rotar and dise issuported on the frame with bearings, and is no longer constrained by it. The inlet and outet are connected by soft connections, whichdoes not afect the force rotation of the balance body. During the design and prodction, the balance an both sides of the balance body isfeeuied pont te the dischar nog der s nne load sasne can aco ately sense the weigm of the powder on the semicircle. ine weight sigmeand impeller speed signal are calculated in the microcomputer to obtain the flow signal, which is compared with the set value and fed backlo the variable frequency speed conirol motor (including the feedcr variabie frequency speed control motor). By adjusting the speed of theweighing machine and feeder,the powder flow rate can be adjusted,

Technical performance:

The weighing machine adopts a balance structure for measurement, with both sides of the alance body balanced.and the sensor only detects the weight of the powder .The zero point of the weighing machine will not change, and the balance will still bemainiained when a small amount of dust acheres io the rotor blades.The incoming and outgoing materials are on the same straight line as the bearings, andthe impact of the incoming and outgoing materials does not affect the balance .The blades are made of a new type of non rigid sealing material that is highly effectivefor powders. There are no dead corners inside the disc, ensuring that all the weighedpowders are transporled away without any measurement errors

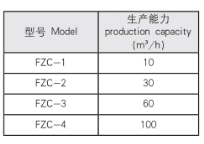

Main technical parameters:

(System dynamiccumulative error):<士0.5%

(Control accuracy):≤± 1.0%

(Feeding capacity):1-100m’/h

(Power):< 10Kw(Control system operating voltage):220V+10% 50Hz±1Hz

(Ambienttemperature):-20℃~5 0’℃

(Relative humidity):<85%

aterial.Powder materials(coal powder, raw material powder, fly ash, etc, )

Reviews

There are no reviews yet.