The RCDD self-discharging electromagnetic iron remover is a high-performance device engineered for precise removal of ferrous impurities in material conveying systems. Typically suspended above conveyor belts or material flow paths, it relies on electromagnetic force—generated by energizing its coil—to create a strong, controllable magnetic field, efficiently capturing iron contaminants (such as bolts, iron chips, or larger iron blocks) mixed in bulk materials like coal, ores, slag, or aggregates.

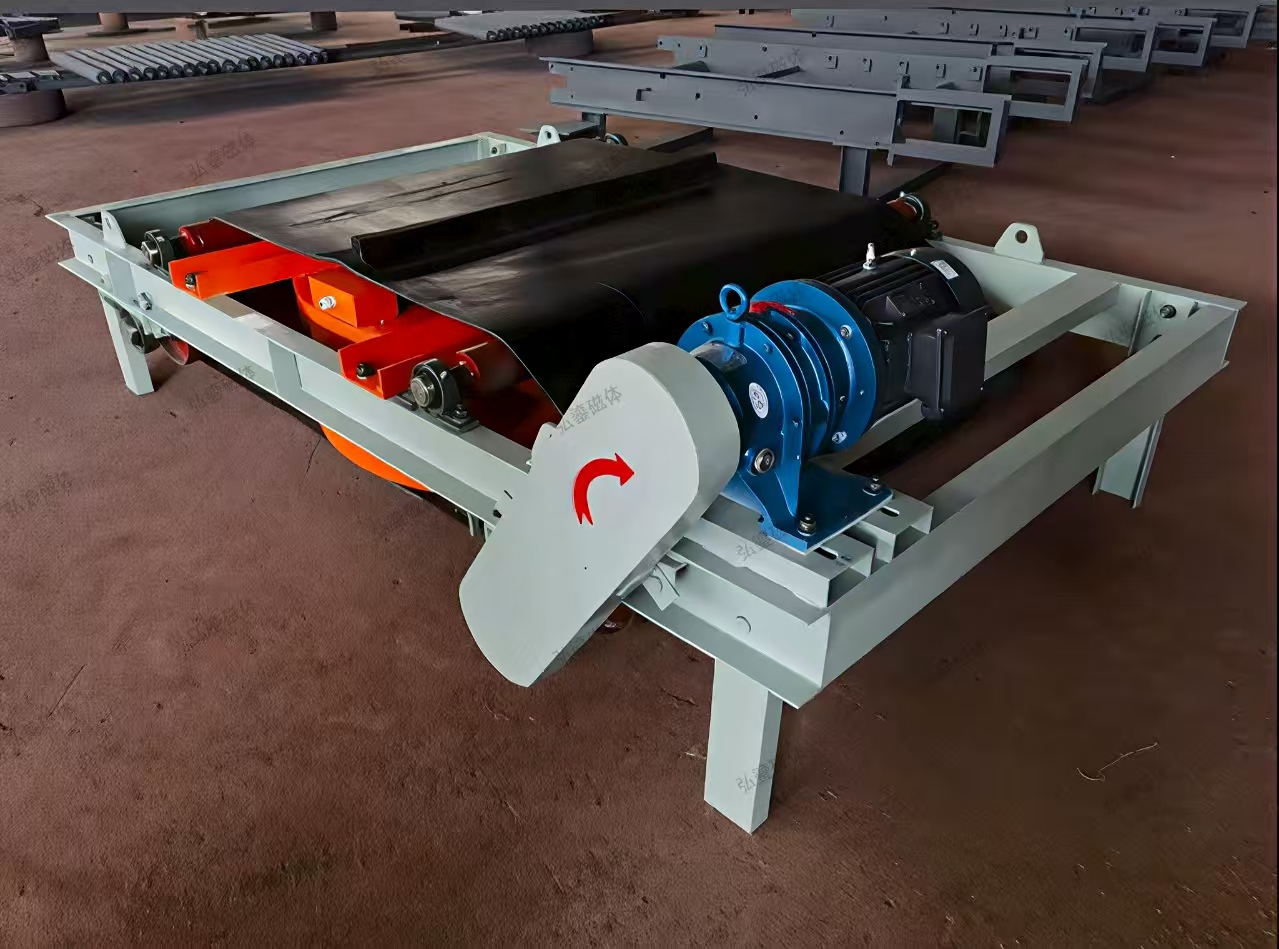

Equipped with an integrated self-discharging system, often consisting of a drive motor, scraper assembly, and discharge chute, the device automatically detaches the adsorbed iron impurities from the magnetic field once the coil is de-energized (or via mechanical scraping), expelling them to a designated collection area. This automated process eliminates the need for manual intervention, ensuring uninterrupted operation of the production line.

Constructed with a rugged steel frame, heat-resistant coil insulation, and wear-resistant contact components, the RCDD is designed to endure harsh industrial conditions, including high temperatures, heavy dust, and continuous vibration. Its electromagnetic system offers flexible magnetic force adjustment by regulating input current, making it adaptable to varying material types and impurity sizes. While it requires a power supply to generate the magnetic field, its efficient energy utilization and stable performance minimize operational costs.

Widely utilized in industries such as thermal power, coal processing, metallurgy, building materials, and chemical engineering, the RCDD iron remover effectively protects downstream equipment (e.g., crushers, grinders, and conveyor belts) from damage caused by iron impurities, improves material purity, and enhances the overall safety and efficiency of production processes.