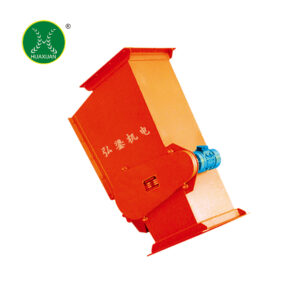

Permanent Magnet Drum Magnetic Separator is a high-efficiency magnetic separation equipment designed for separating magnetic minerals or particles from non-magnetic materials.

Structurally, it consists of a rotating drum (typically made of non-magnetic materials like stainless steel) and a fixed permanent magnet system (usually composed of high-performance ferrite or rare earth magnets) mounted inside the drum. The magnet system is stationary, while the drum rotates around it, creating a stable magnetic field area.

In operation, raw materials are evenly fed onto the surface of the rotating drum via a feeding device. As the drum turns, magnetic particles within the material are instantly attracted to the drum surface by the magnetic force, adhering tightly as the drum rotates. When these magnetic particles move to the non-magnetic zone (where the magnetic field weakens or disappears), they fall off under gravity into the magnetic product collection area. Meanwhile, non-magnetic particles, unaffected by the magnetic field, directly slide down from the drum surface into the non-magnetic product discharge area, achieving efficient separation.

This equipment is widely used in industries such as mining (for processing iron ore, manganese ore, etc.), metallurgy, building materials, and environmental protection. It boasts advantages like compact structure, easy operation, low maintenance requirements, stable performance, and high separation efficiency, making it an essential device for magnetic material processing lines.