Main features:

1. The magnetic field of the electromagnetic dry powder/slury iron remover is high, the magnetic field distribution is uniform, the gradicntis high, and the iron removal effect is obvious.

2. The cooling system adopts forced water cooling for heat dissipation, with good circulatian, which can reduce the tempersture by abou20’C and prolong the service life of the electromagnetic wire.

3. The brake valve is made of imparted materials, The valve body is solid and durable, and there is no residue overflow after closing.

4. The mesh is refined from special materials. After the excitation coil power is cut off, there is no resicual magnetism, which isconvenient for iron removal .

Operating Steps:

1.Connect the power supply device and open the feed valve and discharge valve

2.Close the return valve and iron discharge valve, and open the magnetizing device.

3. After a few mirutes (can be set as required), close the fead valve and discharge valve, and open the retum valve to discharga theremaining materials in the iron remover through the return walve

4.De energize and close the feed valve, discharge valve and return valve

5. Open the iron discharge valve to discharge the iron containing substances adsorbed in the magnetic medium

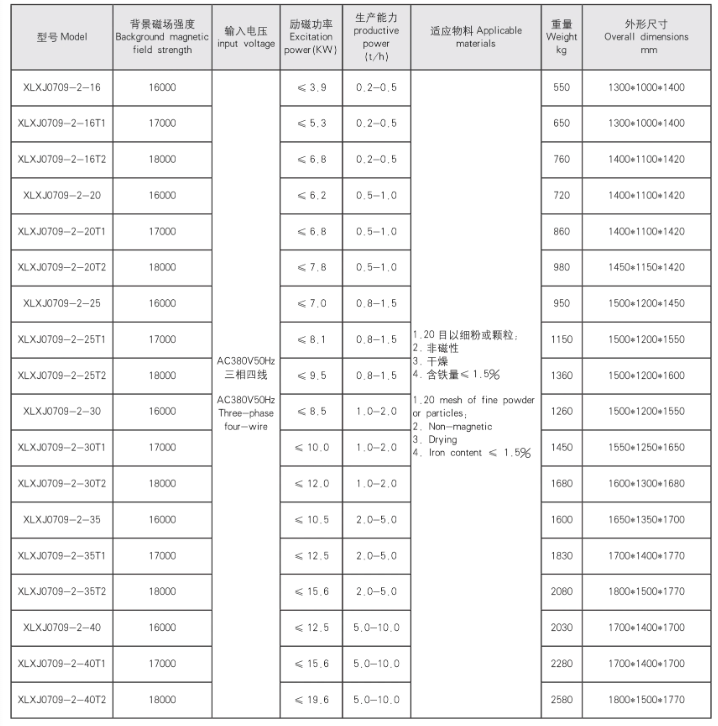

Main technical parameters:

Reviews

There are no reviews yet.