The speed-regulating quantitative belt scale is a critical industrial equipment designed for precise material metering and controlled conveying in various production lines. Integrating advanced load cells, speed sensors, and intelligent control systems, it combines dynamic weighing with adaptive speed adjustment to achieve accurate quantitative material handling.

Its core working principle lies in real-time monitoring: as materials (such as granules, powders, or bulk solids) move along the conveyor belt, high-precision load cells detect the material weight per unit length, while speed sensors track the belt’s running speed. The integrated controller then processes this data—using algorithms to adjust the belt’s speed dynamically, ensuring the actual material flow rate or total dosage strictly matches the preset parameters. This closed-loop control mechanism enables rapid response to fluctuations, maintaining stable and precise quantitative output even with varying material properties.

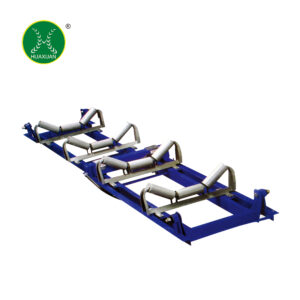

Key features include: high metering accuracy (typically within ±0.5% to ±1%), strong adaptability to different material characteristics (e.g., viscosity, abrasiveness), and seamless integration with automated production systems via standard communication protocols (such as PLC, HMI). It is easy to install, calibrate, and maintain, with a robust structure resistant to harsh industrial environments (dust, vibration, temperature variations).

Widely applied in industries like mining, building materials, metallurgy, grain processing, and chemical engineering, this system optimizes production efficiency by reducing material waste, ensuring consistent batch quality, and supporting data-driven process management. Whether for continuous dosing, batching control, or inventory tracking, it delivers reliable performance to meet strict industrial metering standards.